They are suitable for various sectors, including printed circuit boards (ammonia, nitric acid, ferric chloride), galvanizing, electroplating, chemicals, pharmaceuticals, and incineration/energy recovery plants, as well as composting with odor control.

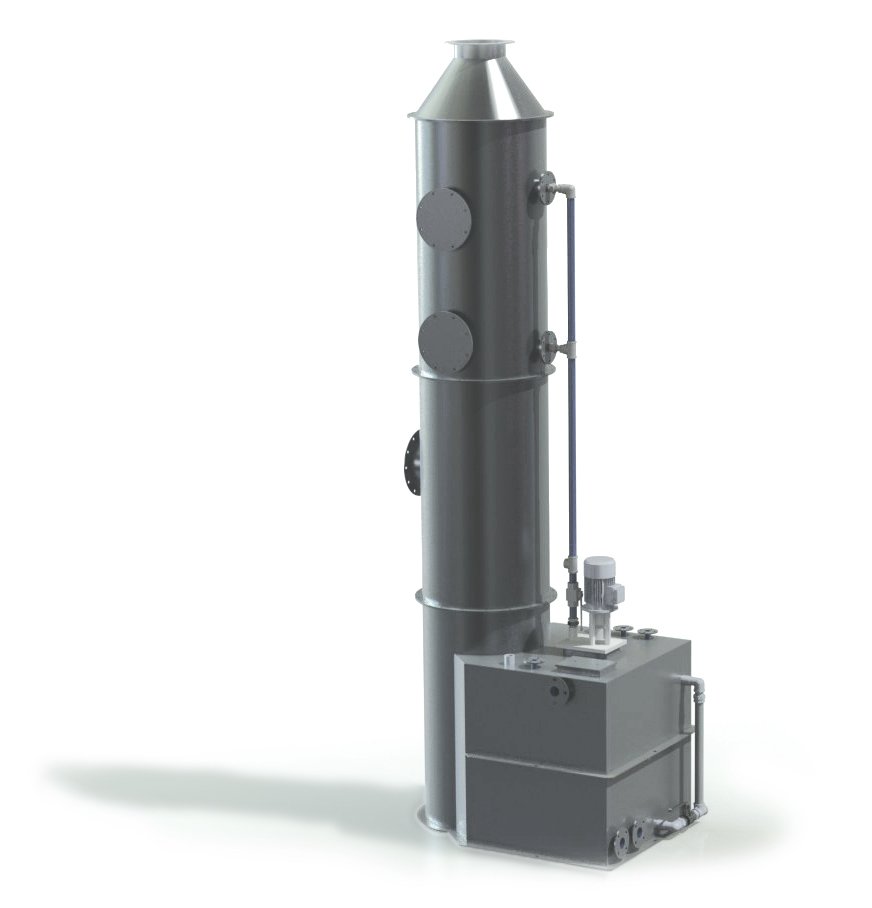

These scrubbers can be made from polypropylene, thermoplastic materials, or stainless steel, offering tailored solutions for specific pollutants. They can feature static or floating cleaning.

They operate by drawing air into the tower from the bottom, where it flows counter to the scrubbing solution. Contact between the liquid and gaseous phases occurs over a surface created by the filling body, supported by specialized grids. This filling consists of materials designed with geometries that provide large contact surfaces.

Standard

- Stainless steel 304 structure

- Demister

- Recirculating pump

- Recirculating pump

- Filing packing

Optional

- Stainless steel316 version

- PP PVC version

- EPDM, PVC or viton seals

- Inspection window

- Scrubber tank

- Electrical panel

- Tank discharge

- Over fill