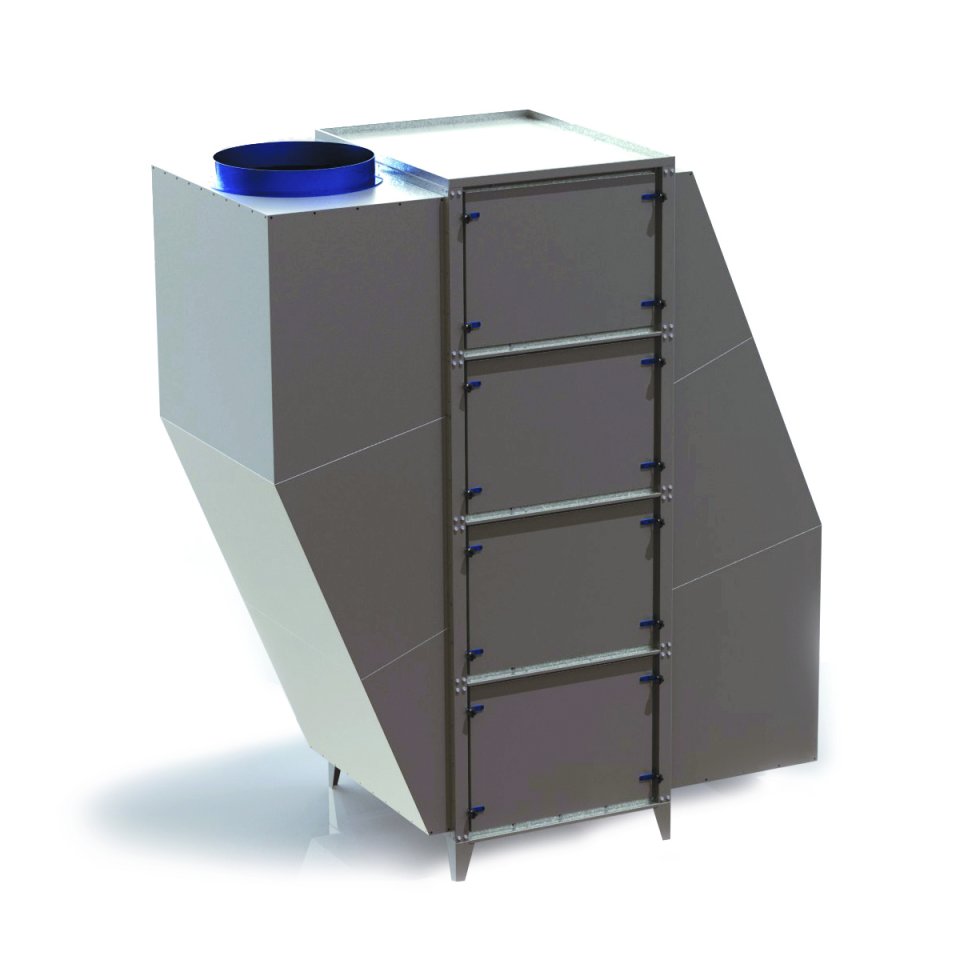

Thanks to the substantial amount of activated carbon, it provides very long saturation times and reduced maintenance. Therefore, it is particularly suitable for treating high air flow rates up to 500,000 m³/h.

Its configuration allows for quick replacement and replenishment of the activated carbon. The discharge of carbon is carried out through discharge hoppers with manual dampers, while loading is facilitated by the hoppers with caps located at the top and accessible via stairs and guardrails.

Standard

- Structure in powder-coated steel

- Activated carbon containment bed

- Manual dampers for carbon discharge from the bottom

- Top caps for carbon loading from above

- Stairs and safety guardrails

Optional

- Air inlet and outlet connections