Prodotti

- Downdraft tables

- Suctioning walls and painting booths

- Compact and mobile dust collectors

- Cartridge dust collectors

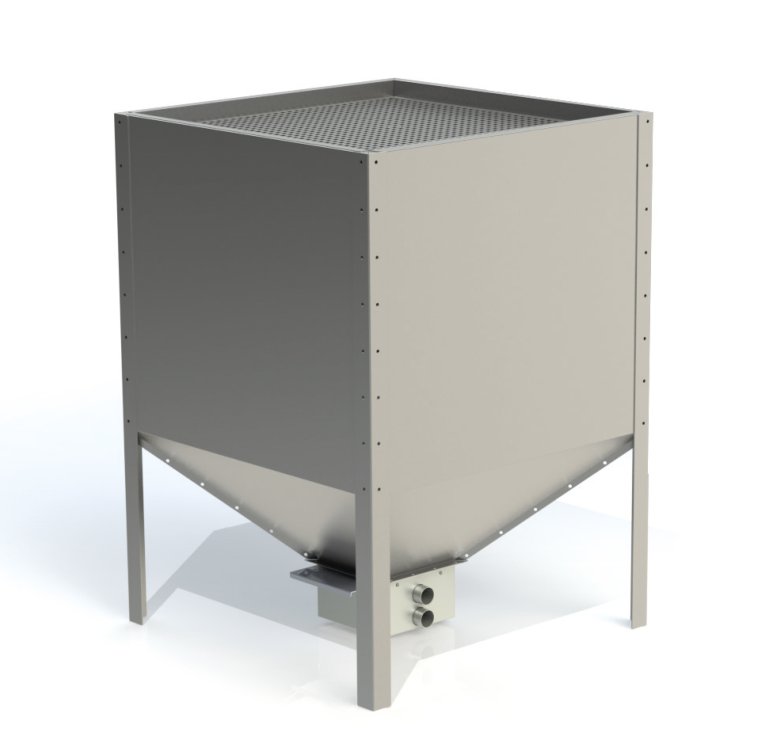

- Baghouse dust collectors

- Candle filters, cyclones, and spark separators

- Rotary Filters

- Fume and mist extractors

- Activated carbon, HEPA and pocket filtering systems

- Scrubber

- Pneumatic conveying and big bag emptying stations

- Aeromechanics