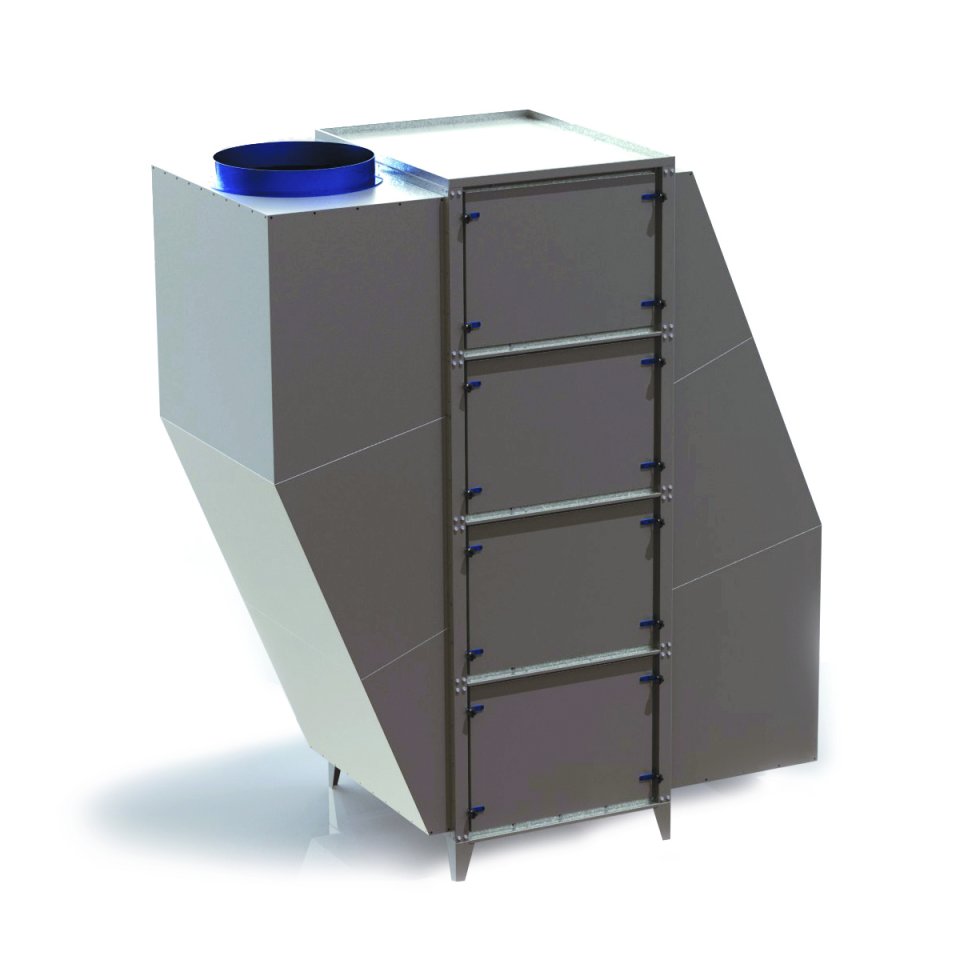

Odor Stop is made of galvanized steel and coated with epoxy powders.

The filter consists of an aluminum body that accumulates contaminants on the internal plates. When saturated, it can be regenerated with a simple wash using water and detergent, ensuring a long lifespan when properly maintained. The initial pressure drop in the electrostatic filter only slightly increases with dirt accumulation, ensuring a long time between maintenance.

Traditional pocket filters have a higher initial pressure drop and increase significantly with clogging, requiring replacement at 300 Pa. Under the same conditions, the ODOR STOP filter shows a much slower increase in pressure drop compared to a pocket filter ePM2.5 50% (formerly F7) and a pocket filter ePM1 70% (formerly F9), which requires three replacements during the same operating period as an Odor Stop.

Additionally, pocket filters result in higher energy consumption compared to Odor Stop electrostatic filters, with an estimated double consumption for a pocket filter ePM2.5 50% and triple for a pocket filter ePM1 70%.

Optional

- Maze filter that ensures the capture of additional possible oil droplets. It is placed before and after the ionizing filter FI.

- The ionizing filter FI ensures greater sterilization and odor reduction.

- Ozonizing filter FX, with plates.

- Stainless steel turbulator to enhance the mixing of air, ions, and ozone.