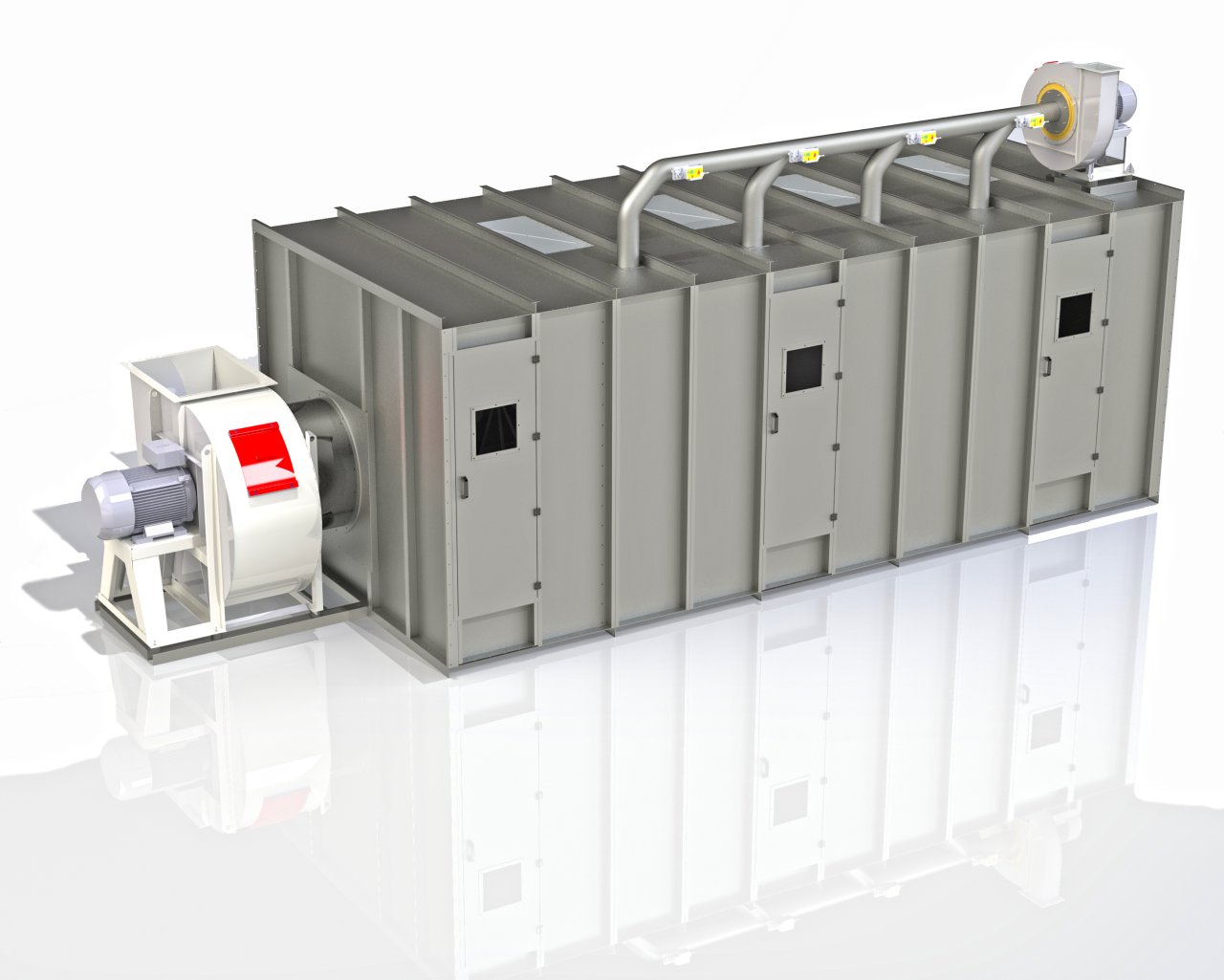

Equipped with strategically positioned dedicated inlets on the sides or roof, the filter efficiently directs the dusty airflow into the chamber. At the core of the system is a perforated basket, meticulously calibrated to the chamber dimensions and airflow velocity. The constant rotation of the basket ensures optimal particle capture, facilitated by the filter partition. Dust particles are securely retained until they are extracted by the fan connected to the suction port, seamlessly reintegrated into the production process.

Subsequent filtration stages include self-cleaning automatic cartridge filters, F7 pocket filters, and HEPA H13 filters. Each section is equipped with access doors and additional lighting.

Efficiency is not just a goal but a hallmark of the Dena rotary filter. Operating at a nominal airflow speed of approximately 0.5 m/s, it features a compact design that maximizes space utilization and minimizes power consumption. Automation, tailored to system needs, ensures smooth operation, while the robust construction using treated and painted S235JR steel guarantees longevity and durability.

Safety is paramount, reflected in every aspect of the Dena rotary filter design. Explosion-proof panels protect against potential hazards, complemented by a series of safety measures including access doors with safety micro-switches, internal LED lighting, and a fire alarm system circuit.

Details and Accessories

Dena filters are built to last. High-quality materials are used for construction and coated with the chosen RAL color for protection. All our products are meticulously designed by a team of experienced technicians who consider even the smallest details.